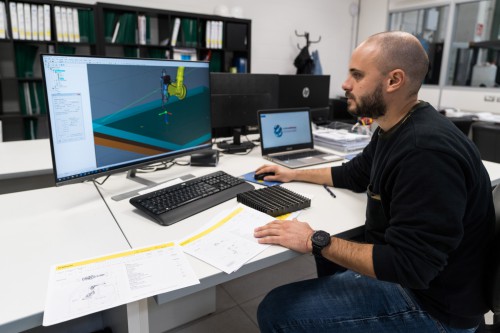

Industrial engineering

STUDIO CATTANEO srl PLANTS DIVISION offers its customers many choices for solving problems related to the production, the performance of existing plants, the flexibility, the development of new technologies, or to the UP grade of existing plants.

In fact the service start from the engineering process analysis to pass to the systems design, to the mechanical, electric and electronic assembly, to the first testing in the local facility to finalize it with the start up in any customer location worldwide.

The prompt reaction to the customer needs, either for a simple assistance or for a machine small upgrading, given when possible even by phone as a free tip, allows the technicians to be “close” to the production plants and to the end users.

The believe is that the customers increasingly grown in their number during the last few years, because they highly appreciated this working approach.

The high specialization in the field of steel processing, welding and robotic automation, allows us to meet and exceed all the production requirements of our customers.